24/05/23

Discover Our Range of Sanden and Unicla AC Compressors

At Adigo, our commitment to supplying quality products and solutions for vehicle applications is evident in our diverse product portfolio. We leverage our extensive expertise to meet your needs with top-tier offerings from both Sanden and Unicla, leaders in the field of AC compressors.

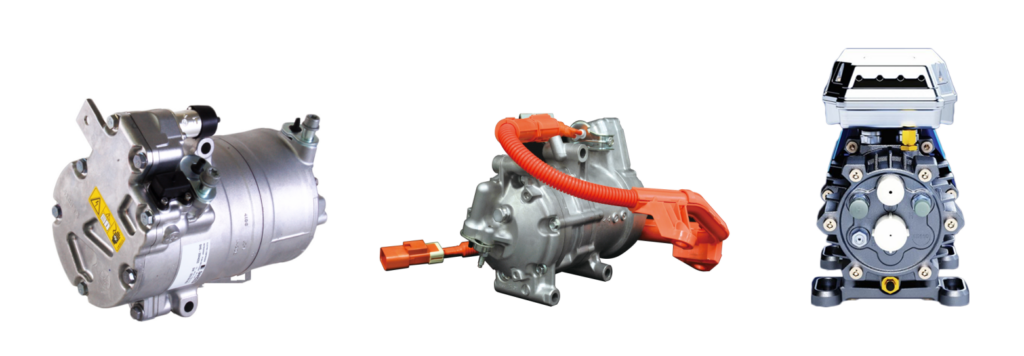

Versatility of Sanden and Unicla Compressors

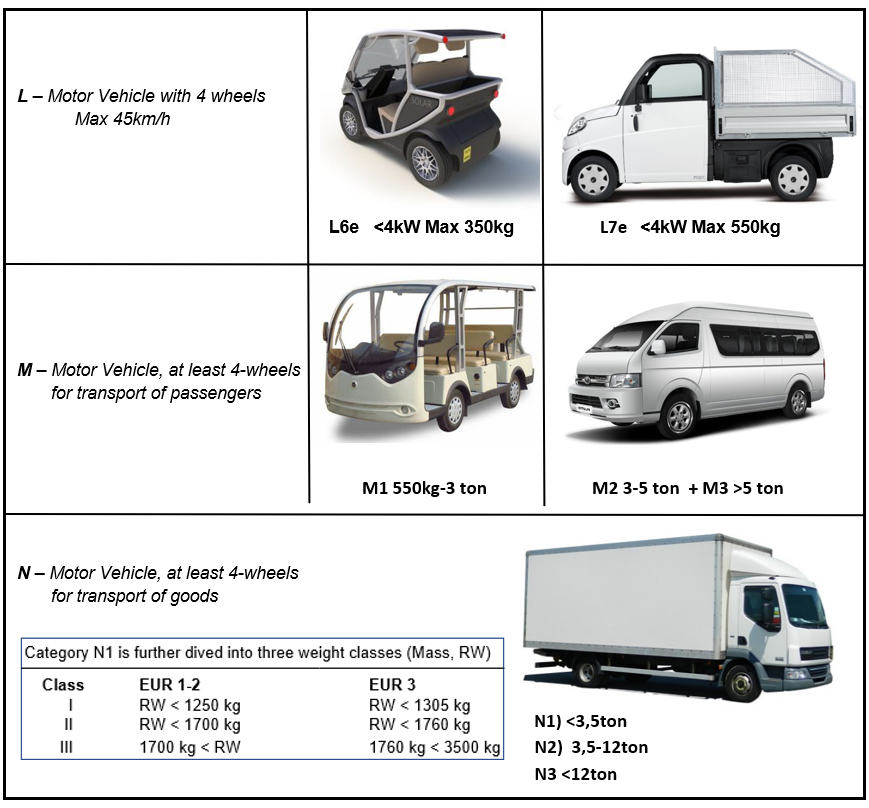

Sanden and Unicla compressors excel in a wide range of applications. They are ideal for use in Internal Combustion Engine (ICE) vehicles, Plug-in Hybrid Electric Vehicles (PHEV), and Battery Electric Vehicles (BEV). Additionally, they are well-suited for cabins on buses, heavy machinery, cooling trucks, and cargo vehicles. Our compressors can be belt-driven, electric, or hydraulic-driven, showcasing their adaptability and broad utility.

Explore Our Sanden Compressor Range

Sanden is known for producing high-quality, durable AC compressors tailored for various applications, especially excelling in the automotive market for passenger cars. These compressors ensure efficient and reliable cooling, which is crucial for the optimal performance of modern vehicles.

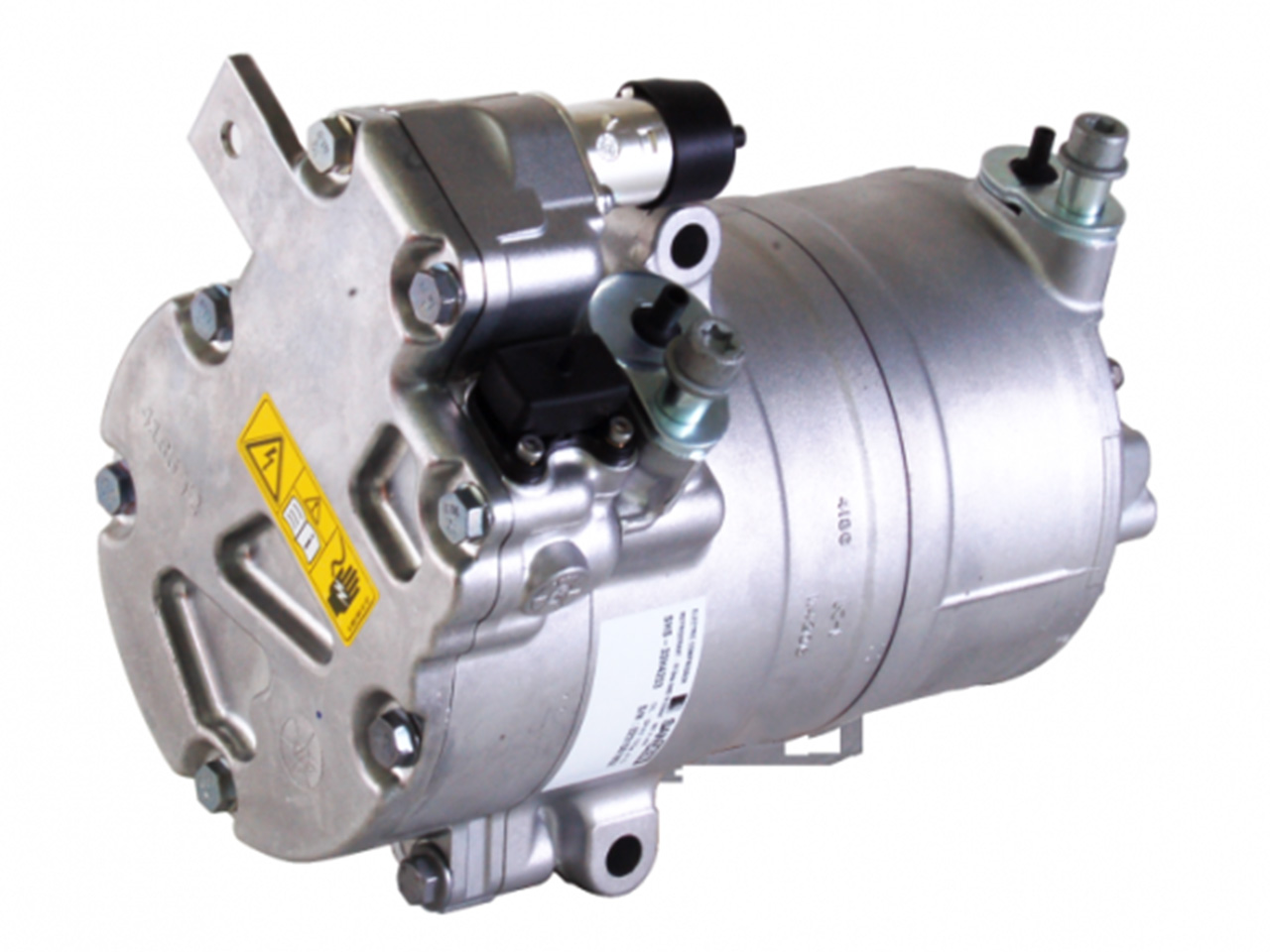

Sanden Electric Compressors

The Electric Compressor Series from Sanden is designed for modern electric vehicles. These compressors offer efficient and reliable cooling with low noise emissions, ensuring optimal performance for battery thermal management and integrated cooling solutions.

Download overview of Sanden AC Compressors.

Sanden Compressor Range

Electric Compressor Series: Featuring advanced technology for electric vehicles, providing low noise and high efficiency.

PX Series: Known for its efficiency and reliability, ideal for a range of vehicle applications.

SDH Series: High-performance compressors that cater to diverse needs.

SHD and SSHD Series: Super Heavy Duty and Semi Super Heavy Duty models designed for extreme environments, ensuring durability and longevity.

TR Series: Scroll compressors that provide high efficiency and low noise operation, suitable for high engine speeds.

Universal Compressors: Flexible configurations to fit various systems, suitable for aftermarket and niche OEMs.

Explore Our Unicla Compressor Range

Unicla is renowned for their large capacity and robust compressors, making them perfect for heavy-duty applications with capacity up to 32kW and 675cc/rev! Highlighted below are two of their standout products:

Unicla eDrive Compressors

The eDrive Series are electric compressors specifically designed for electric vehicles. These compressors feature onboard control electronics and firmware that optimize performance across different systems, providing efficient and reliable cooling. Ideal for modern electric vehicles, the eDrive compressors ensure top-notch battery thermal management and integrated cooling solutions.

Unicla Hydraulic Compressors

Unicla’s Hydraulic Compressors are designed for high performance in hydraulic applications, providing reliable and efficient operation even in the most demanding environments. These compressors are built to withstand heavy-duty usage, making them ideal for applications in construction, agricultural, and industrial sectors.

Other Unicla Compressor Ranges

200 Series: Suitable for moderate capacity needs.

300 Series: Increased capacity for more demanding applications.

400 Series: Advanced capacity for heavy-duty requirements.

500 Series: High capacity for extensive use cases.

600 Series: Ultra-high-capacity compressors for extreme applications.

Discover More

To explore our full range of AC compressors from both Sanden and Unicla, visit our website or contact us directly. We are here to provide you with the latest advancements in cooling technology, tailored to your specific needs.

Read more>