The future emission work has already started

Electrification of the Heavy-duty vehicles and the demand from the end-customers is growing. Today lorries, buses and coaches are responsible for about a quarter of CO² emissions from road transport in the EU and for some 6% of total EU emissions. Despite some improvements in fuel consumption efficiency in recent years, these emissions are still rising, mainly due to increasing road freight traffic.

From 2025 on, manufacturers will have to meet the targets set for the fleet-wide average CO² emissions of their new lorries registered in a given calendar year. Stricter targets will start applying from 2030 on. The targets are expressed as a percentage reduction of emissions compared to EU average in the reference period (1 July 2019–30 June 2020):

* from 2025 onwards: 15% reduction

* from 2030 onwards: 30% reduction

Setting Course for 2025

Can Oslo and Amsterdam meet the environmental demands for 2025?

Norway’s main parties appear to have agreed on the fate of the internal combustion engine. Together with Netherlands who also is a part of the ZEV organization, The International Zero-Emission Vehicle Alliance there will be prohibition applied for the new sale of cars with gasoline or diesel engines in 2025. With Oslo’s and Amsterdam’s rapid growth, the scarcity of energy, and the importance of a healthy living environment, the need for cleaner, more energy-efficient vehicles is greater than ever. The question is, will this short time suffice?

For passenger cars it’s partly solved but how will this affect the EUV vehicles? Many heavy-duty vehicles also have the environmental requirements. A typical EUV in the cities primarily are building roads, ground facility, excavation and other roadworks. Here is a larger challenge where a few manufacturers just started their trip towards electrification. Does the market have the knowledge in replacing the combustion engine with an electrical drive-chain, adding functional power and motor controls to fit the requirements. Many functions vehicles have will also be replaced with electromechanical components.

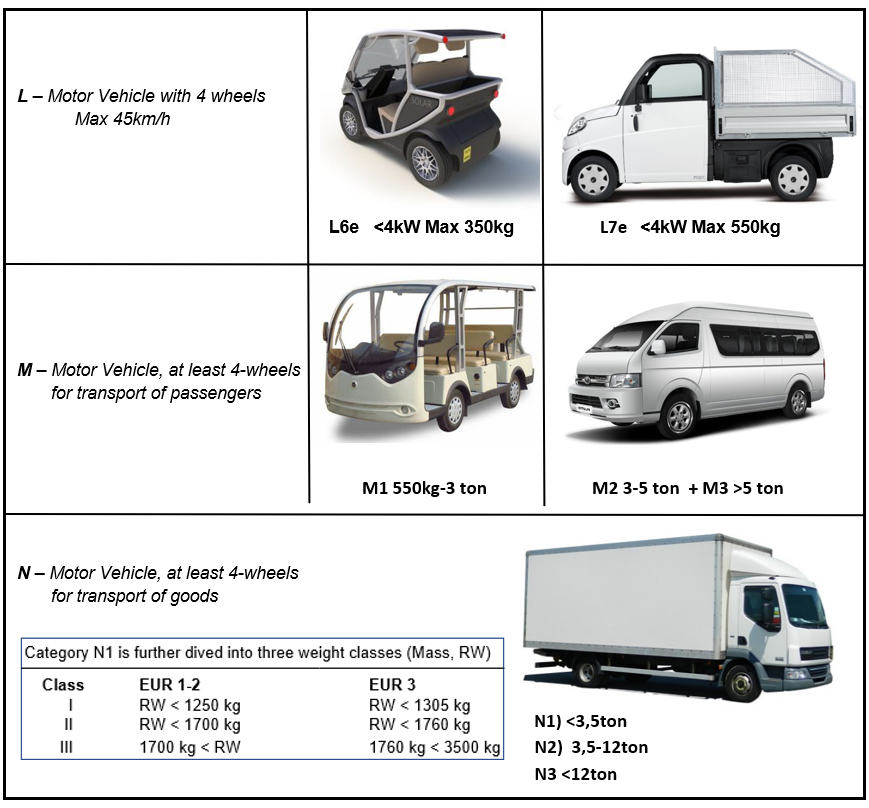

Classification of Electric Vehicles

If the vehicle weighs from 300kg it fits into a standard in below chart as an EUV. Categorize L, M and N. The European Commision classifies vehicles as part of emission standards and other vehicle regulations. Two directives of the European Parliament and of the Council serve sources for these definitions and classifications

(2013/168/2019 of 20-Feb-2019 and 2007/46/2019/EC of 01-Sept-2019) Source: https://eur-lex.europa.eu/homepage.html

What aspects are to be considered for getting there in 5 years?

- Technical requirements

The market for commercial electric vehicle projects involves designing a high speed and high power electric motor that would be used with a gearbox. To design the entire electric powertrain of larger four-wheeled vehicles weighing from 300 kg up to several tons you need to know the defined environment that it will be operating in to choose which parts are involved to electrify this vehicle. It applies aspects such as engine and controller comparisons, estimated technology level of entire system. Is it a direct-drive in-wheel, transaxle or hub motors, do you need to replace with other components when you’re changing the drive-system? What kind of power source will be needed to run the vehicle?

- Efficiency

The customers need could be a more specific propulsion unit that must be adapted to different external conditions and aims to reach a high efficiency. A gearbox can be part of the solution when it comes to increasing efficiency of a powertrain or a combination of hub motors and transaxles, how can this be integrated without changing too much in the driveline. While the peak efficiency of the AC Induction motors can be as high as PMDC motors, the high efficiency can only be maintained at a certain operating spot. This should also set into the entire drive cycle analysis and choice of technology in the drivetrain. The variations of drivetrains that will be the solutions on the EUV market will be greatly diverse and highly specific to the area of use for the vehicle.

- Design

Another requirement that often arises is the fitting of the components in confined/given spaces. The bus and trucks OEM’s rarely want to do changes in their vehicles or in their production lines, simply for the purpose of incorporating a new powertrain. Direct-drive in-wheel or hub motors or transaxles, on the other end, often require a special axle or the customization of other vehicle parts in order to be properly integrated. Fitting as much battery into the current chassis is already quite a challenge. When such an EUV OEM company shall design or redesign such a chassis they need to entirely use a new engineering pattern and process from how they are used to and ask questions never asked in their organizations.

- Usability vs Power source

In order to optimize the batteries for the perfect combination of vehicle propulsion and performance with a maximized user time, you also need to consider the total energy consumption. Today you take your vehicle to the gas station but how will we accomplish this change with upcoming technology? When, how and where will you get your vehicle charged, will it be made slowly during night-time or a fast charged during your lunch break? We do understand that it is a challenge and that the infrastructure must be updated with this technology. But with the right expertise in development, this will be solved in the best way.

- Maintainance

There are many advantages using electric vehicles, but of course there is a maintenance cost, as with other vehicles. Maintenance is also about being able to access, diagnose and replace a product as easy as possible when a problem occurs. A motor system integrated with multiple other components such as a gearbox assembly or inside a wheel might be hard to access on a standalone basis. Such scenarios can make maintenance more complex or costly. Despite this, it is a selling point-in-favor of EUV’s as the costs in relation to ordinary vehicles are expected to decrease.Do you have this challenge ahead of you? – Contact Adigo for professional help to develop your EUV