Adigo - Your Partner in Battery System Integration

Adigo is your trusted partner for battery system integration needs. As experts in electrification, we are committed to providing innovative and reliable battery solutions for all contemporary needs, and we also keep an eye towards the future.

Lithium-Based Battery Systems

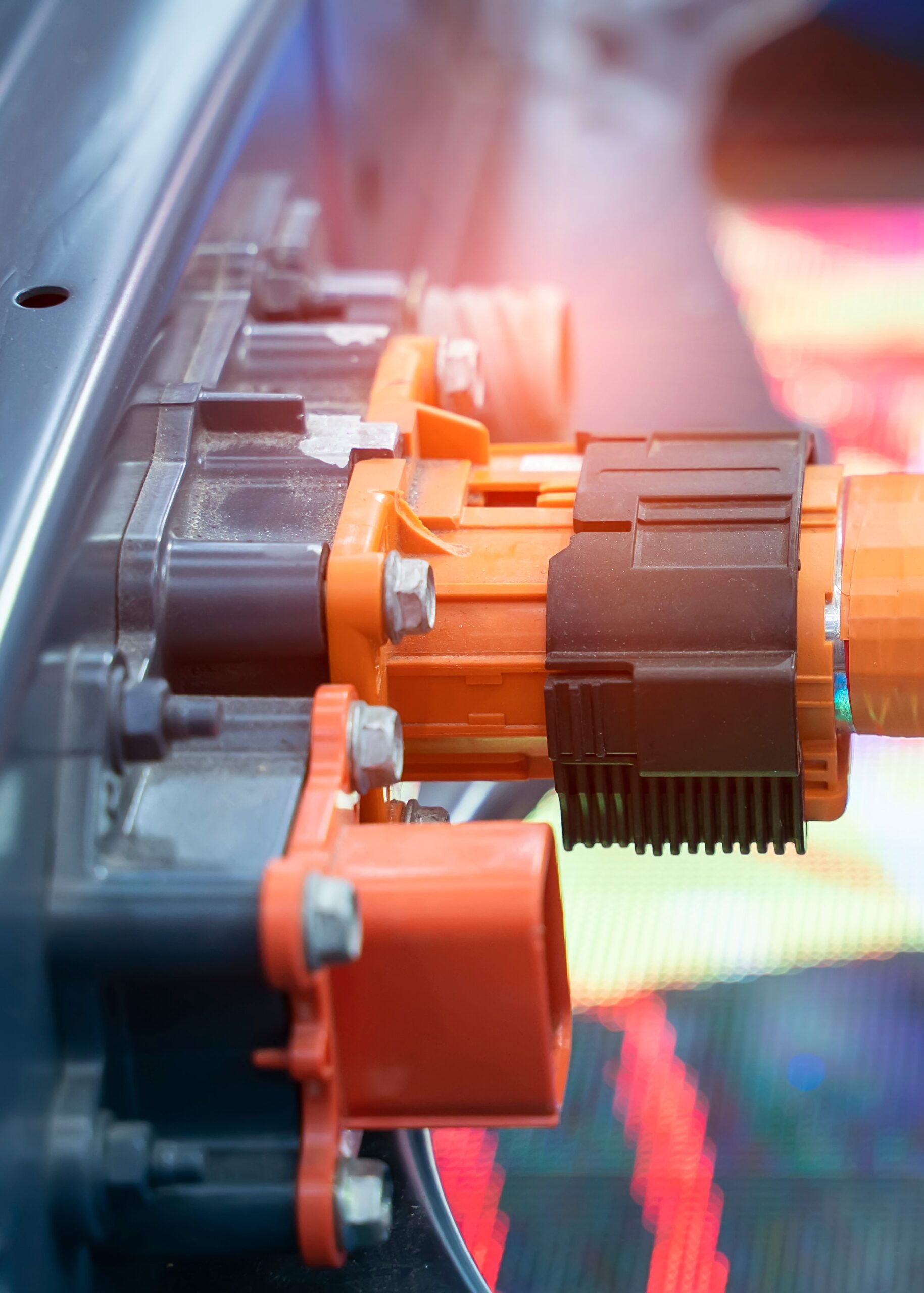

We specialize in working with lithium-based batteries ranging from 24V to 800V to provide you with battery systems that are efficient, lightweight, maintenance-free, and have a small ecological footprint. We can help you build the battery system you require, from individual battery cells to full battery systems, depending on your specific application and requirements.

We have experience in designing and developing battery packs for a variety of applications, including and off-highway vehicles, material handling equipment, marina, utility vehicles to name a few. We understand how our customers’ machines work and we can optimize the battery system to match their specific needs.

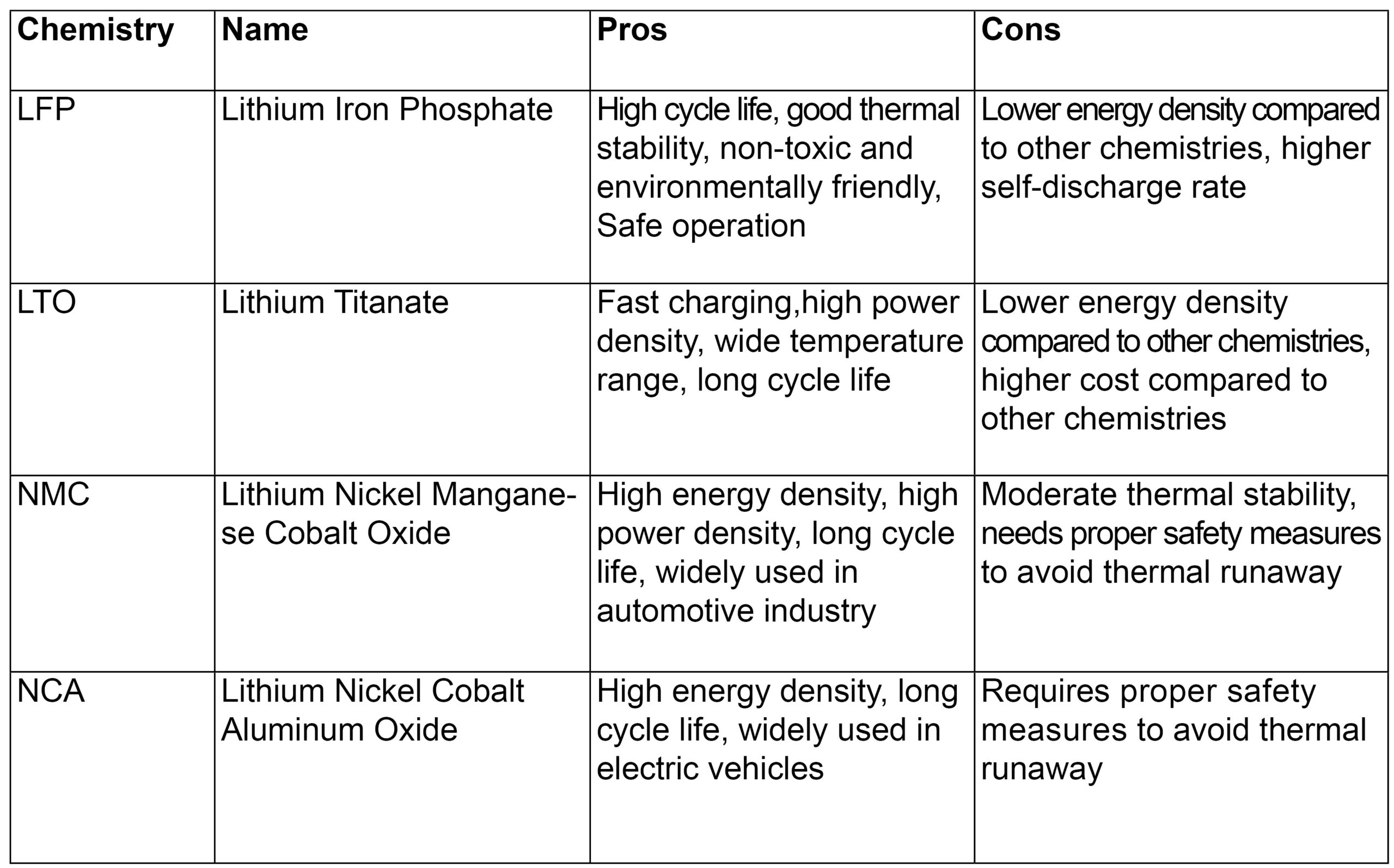

Lithium Battery Topologies

To give you an overview of the different lithium battery topologies we work with, we’ve created a table of the most common types along with their pros and cons:

Standards and Certifications

When it comes to battery systems, there are various standards and certifications that need to be considered to ensure safety, reliability, and compliance. Some of the relevant standards and certifications that we follow include:

• UN 38.3: This is a standard that provides guidelines for the safe transport of lithium batteries. Compliance with this standard is mandatory for any lithium battery shipment.

• ISO 26262: This is a functional safety standard for road vehicles. It outlines a risk-based approach to ensure the safety of automotive systems.

• ISO 6469: This is a standard that specifies requirements and test procedures for high-voltage batteries used in electric vehicles.

• IEC 62660: This is a standard that specifies test procedures for lithium-ion cells used in electric vehicles.

• CE: This is a certification that indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

• UL: This is a certification that indicates compliance with safety and performance standards for products sold in the United States.

Bespoke Battery Packs

We understand that every application has unique requirements, and that’s why we offer bespoke battery packs that are customized to meet your specific needs. To ensure that we can provide you with the right solution, we have a questionnaire that we use to gather information about your requirements. Here are some of the questions that we typically ask:

• What is the intended use of the battery pack?

• What is the required energy capacity?

• What is the required voltage?

• What are the size and weight requirements?

• What is the operating temperature range?

• What is the desired charging time?

• What safety features are required?

By gathering this information, we can design and build a battery pack that is tailored to your needs and specifications.

Partner with Adigo for Your Battery System Integration Needs

Adigo is a trusted partner in electrification projects, providing battery systems for various applications. With expertise in battery pack design, development, and assembly, Adigo can create bespoke battery systems to meet the specific needs of its customers. By using the latest lithium battery topologies and ensuring compliance with relevant standards and regulations, Adigo’s battery systems are reliable, safe, and fit for purpose.