24/09/19

ELEMATIC – Preparer E9

Customer: Elematic

Application: Casting bed preparation

Segment: Precast concrete machinery

Stage of involvement: Case study

Powering Innovation Together—Adigo Drives and Elematic Preparer E9

Adigo Drives and Elematic have teamed up to deliver a groundbreaking solution in the precast concrete industry. Our collaboration on the Preparer E9 is a perfect example of how advanced electrification can revolutionize traditional processes, enhancing efficiency, precision, and sustainability.

About Elematic and the Preparer E9

Elematic, a global leader in precast concrete technology, consistently sets the bar for innovation in the construction industry. Their products are designed to streamline operations, improve quality, and reduce costs in precast production. The Preparer E9, their latest innovation, exemplifies these principles, offering a state-of-the-art solution for preparing precast concrete floors with unmatched accuracy and reliability.

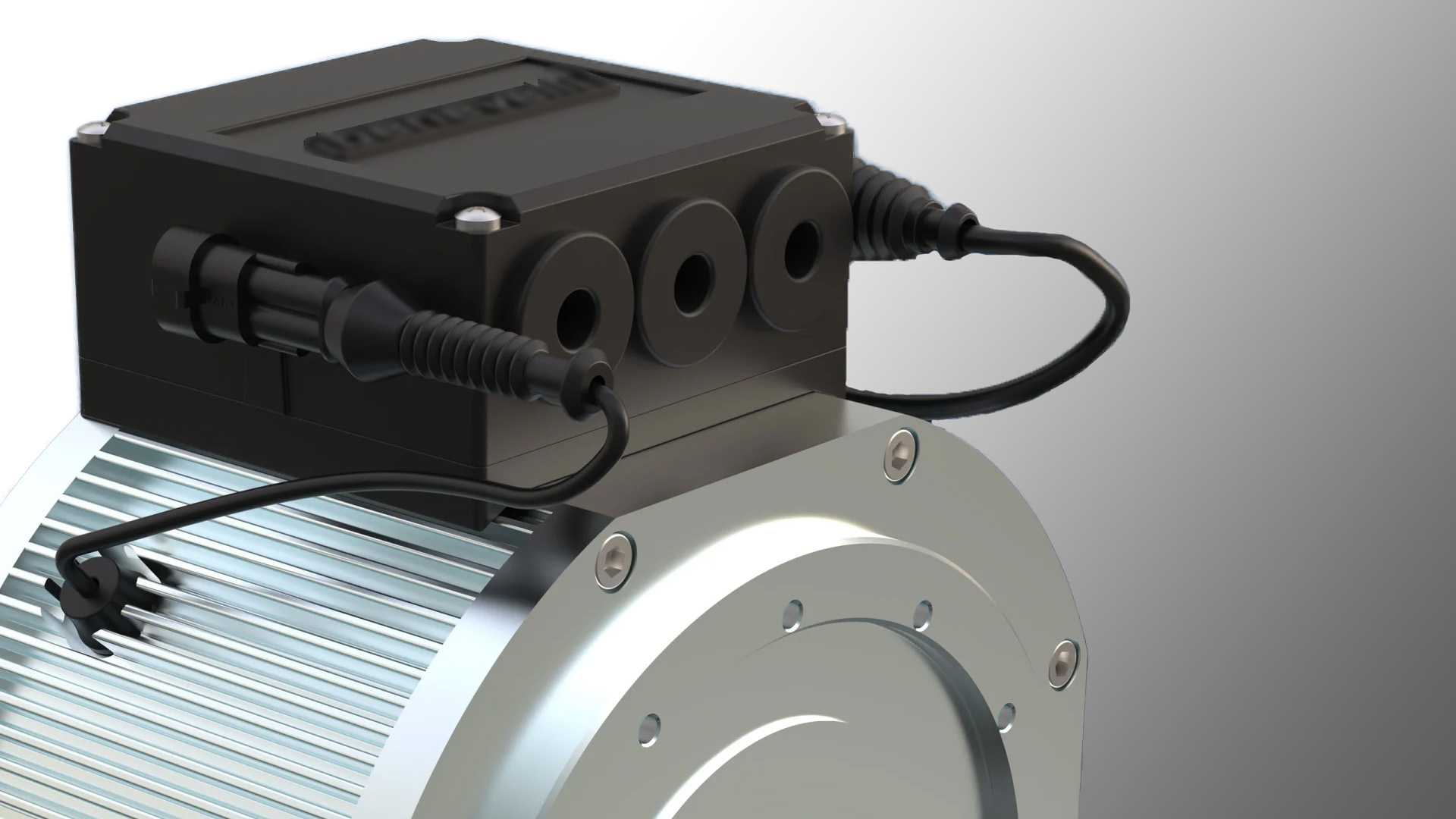

Adigo Drives’ Role: Electrifying the Future

At Adigo Drives, we specialize in electrification solutions that push the boundaries of what’s possible. For the Preparer E9, we provided cutting-edge electric motors and motor controllers, transforming it into a fully electric system. But what does that mean in technical terms?

Technical Highlights:

The electric motors we integrated into the Preparer E9 are based on IPM topology and are supplied by E-comer. Specifically, we used the SMAC series of IPM motors, which are designed for heavy-duty performance, delivering high torque with exceptional precision. This is vital in the demanding environment of concrete preparation, where consistency and control are paramount. Our motors are paired with advanced motor controllers from DMC, specifically the SuperSigma 2 controllers, which feature outstanding performance. This ensures that the Preparer E9 maintains optimal performance, regardless of varying material densities or environmental conditions.

One of the most significant benefits of electrification is the reduction of noise and elimination of emissions. The Preparer E9 operates quietly and cleanly, making it ideal for indoor use and aligning with the growing emphasis on sustainable construction practices.

The Results: Efficiency, Precision, and Sustainability

The collaboration between Adigo Drives and Elematic has yielded significant benefits:

– Enhanced Efficiency: Our electrification solutions enable the Preparer E9 to operate more efficiently, cutting energy consumption and reducing operational costs.

– Precision Control: The advanced control systems provide the exacting precision required for high-quality precast concrete production.

– Sustainable Operation: The move to a fully electric system eliminates harmful emissions and significantly reduces noise, contributing to a safer, more sustainable work environment.

– Silent and Zero Emission: No emissions make it possible to use inside and being silent improves working environment and communication with colleagues.

Why Choose Adigo Drives?

Partnering with Adigo Drives means choosing a company that’s committed to innovation, precision, and sustainability. Our work with Elematic on the Preparer E9 highlights our ability to deliver advanced electrification solutions tailored to meet the specific needs of our partners. Here’s why you should consider working with us:

– State-of-the-Art Technology: We leverage the latest in electrification technology to provide superior solutions.

– Customized Solutions: We tailor our offerings to fit your unique operational needs and goals.

– Ongoing Support: Our team is dedicated to supporting your project from concept to completion, ensuring success at every stage.

In Conclusion

The partnership between Adigo Drives and Elematic on the Preparer E9 is a testament to the power of advanced electrification. Together, we’re driving innovation in the precast concrete industry, setting new standards for efficiency, precision, and sustainability.

Interested in learning more about Elematic and the Preparer E9?

Read more>